Pro Surface Prep Methods to Elevate Ceramic Coating Results: Expert Guide and Techniques

GET A FREE ESTIMATEDecember 16, 2025

Getting a ceramic coating on your car can make the paint look amazing and protect it for years. But here's the deal: no matter how effective the coating is, it won't work well if the surface underneath isn't properly prepared. Dirt, imperfections, and invisible contaminants can stop the coating from bonding right, which means dull spots or peeling down the road. That's why taking the time to clean, decontaminate, and polish your car carefully before applying any product is key to getting that smooth, glossy finish that really lasts. Professional surface prep methods to elevate ceramic coating results include thorough washing, contaminant testing with the baggie test, claying to remove bonded impurities, and machine polishing to eliminate micro-imperfections and chemical residues. Performing these steps in a controlled environment ensures optimal bonding, maximum gloss, and extended durability of the ceramic coating.

Selecting the Right Products

When it comes to preparing your car's surface for a ceramic coating, not all cleaning and polishing products are created equal. Using high-quality materials designed specifically for automotive care can dramatically improve how well the coating bonds with your paint and how long it lasts. A pH-balanced car shampoo is essential because it cleans without stripping away existing waxes or sealants that protect your car. This gentle cleansing ensures the surface is free of dirt but still primed for more intensive treatments.

Similarly, clay bars play an indispensable role beyond traditional washing. These special bars remove stubborn bonded contaminants like tree sap, industrial fallout, and brake dust that ordinary soap cannot tackle. Using an automotive-specific clay bar reduces the risk of marring your paint since these products are formulated to glide smoothly yet pull impurities off the surface. Polishing compounds don't just make your paint shine; they actually correct imperfections on the surface. This step smooths out the surface on a microscopic level, allowing the ceramic coating's liquid polymer to form a stronger chemical bond with the paint beneath. Skipping this means you could trap those flaws under glassy layers of coating that only become more visible later. Opting for professional-grade ceramic coatings typically means working with higher concentrations of silicon dioxide, which equates to a thicker, more resilient protective layer. While these require careful handling and precise application techniques, the payoff is undeniable longevity and a mirror-like finish that repels water and dirt naturally.

Removing Surface Contaminants

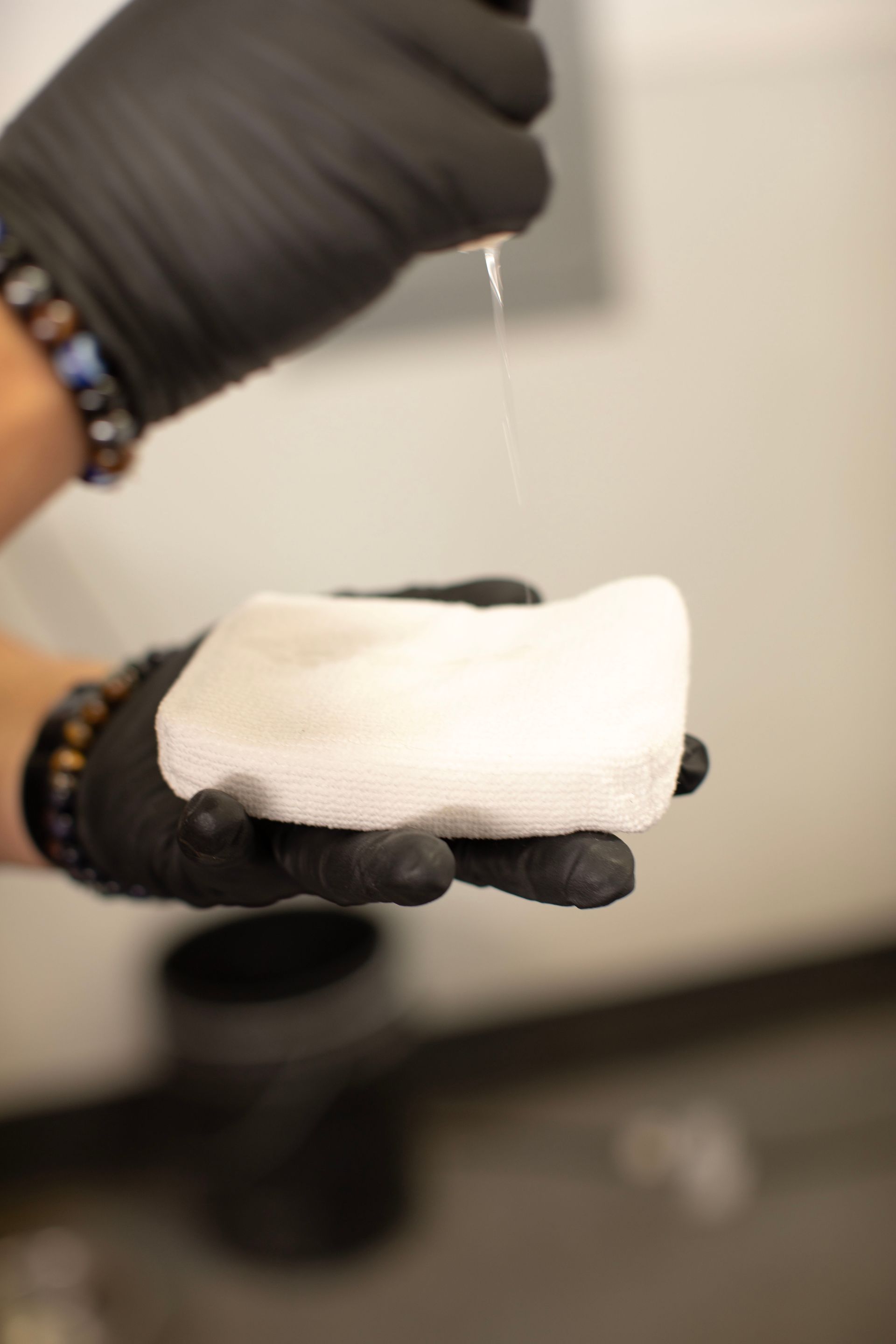

When you look at a freshly washed car, it might seem clean enough for ceramic coating. However, appearances can be misleading. Tiny particles like rail dust, industrial fallout, tree sap, and road grime often cling stubbornly to paint; they're so small they're invisible to the naked eye but big enough to disrupt proper coating adhesion. These contaminants form an invisible barrier that prevents the coating from locking in tightly, which shortens its protection and dulls the finish over time. That's why the baggie test is such a game-changer in detailing. Simply slip a thin plastic bag over your hand and glide it gently over the paint surface. The bag magnifies tactile sensitivity, and if it feels rough or gritty, you know contaminants are still lurking beneath the shine. This quick test reveals dirt your eyes miss.

Once contamination is detected, clay bar treatment becomes your best friend. Clay bars are specially formulated blocks of synthetic resin designed to lift bonded particles clean off your paint's surface without damaging it. Start by generously misting the area with a lubricant made for claying. Lubrication is critical because rubbing dry clay directly against paint can cause micro-imperfections. Then gently move the clay bar back and forth in straight lines. This controlled movement optimizes contaminant removal while minimizing risk. Frequently knead the clay into a fresh pad as it picks up debris, and once it's saturated or noticeably dirty, discard it and grab a new piece. The magic here is transforming a rough-feeling surface into one that glides smoothly under your hand. This silky smoothness is essential for proper ceramic coating application because it ensures maximum bonding with the clear coat beneath. It's also wise to combine claying with chemical treatments like tar removers or iron fallout dissolvers if stubborn contaminants resist physical removal. These specialized products chemically break down impurities that clay cannot reach alone. Just remember to rinse thoroughly afterward and follow up with an IPA wipe-down to remove any oils or residues left behind.

Polishing Methods for Smooth Finish

Polishing is what truly elevates your vehicle's paint from merely clean to mirror-like smooth. It works by delicately removing micro-imperfections, oxidation, and subtle defects that remain invisible to the naked eye but drastically affect gloss and coating adhesion. Unlike hand polishing, which often lacks the power or control needed, machine polishing offers consistent results and superior correction without excessive effort. Using a random orbital polisher strikes an effective balance between safety and performance. These devices provide controlled, vibration-minimized motion that reduces the risks of creating new haze while delivering that coveted deep gloss. Pairing your polisher with the right pads and compounds tailored to your paint's condition guarantees the best outcome.

Start with a softer foam pad and a mild polish to gently loosen imperfections, then move up to more intensive pads and compounds only if stubborn defects persist. Starting with too aggressive a compound can damage the paint, losing you precious time restoring the finish later. Instead, begin cautiously and build up intensity as needed. During polishing, maintaining appropriate pressure, about three to five pounds, and keeping speeds moderate is essential to prevent heat buildup. Excessive friction causes paint damage or burns through the clear coat, undermining the entire prep process. Work in controlled environments free from dust, wind, or direct sunlight. The right humidity and temperature range, around 20 to 25 degrees Celsius and 40 to 60 percent humidity, create an ideal workspace that improves polish residue removal and overall quality. Once you've polished each panel thoroughly, inspect your work carefully under bright lighting to illuminate remaining haze easily missed in ambient daylight. Repeating targeted polishing on these areas solidifies your surface's perfection, creating a smooth, even base where ceramic coatings bond strongly and reliably.

Applying Ceramic Coating

Ceramic coating application demands patience and a steady hand. The process hinges on creating an even, thin layer that bonds tightly to your vehicle's paint. Begin by working in a clean, enclosed space to avoid dust landing on the wet coating. The ideal temperature sits comfortably between 10 and 21 degrees Celsius, ensuring the coating cures properly without drying too quickly or staying wet too long. Before dipping your applicator, make sure the vehicle's surface is fully dry and free from oils or residue. This is often confirmed through an Isopropyl Alcohol wipe test, which reveals hidden contaminants invisible to the naked eye. Use a suede applicator wrapped around a foam block because this combination gives you control over how much liquid you apply and where. Apply just a few drops of the ceramic solution onto the applicator; using too much leads to difficult buffing later and uneven coverage. Work systematically in small sections, roughly two square feet at a time. The crosshatch pattern—smooth horizontal strokes followed by vertical ones—ensures that no area is missed and helps the coating form a uniform layer.

After applying, you'll notice the coating begins to flash or change appearance, typically within one to five minutes depending on ambient conditions. Flashing indicates the solvent is evaporating and the ceramic particles are starting to bond with the paint. Once flashing occurs, gently buff off any excess product using a fresh, clean microfiber towel. Light contact prevents damage while still removing oily residues. Most experts recommend applying two to three layers of ceramic coating for longer-lasting protection. After completing each layer, wait about 10 to 15 minutes before starting the next application. This staged approach builds both hardness and a water-repellent gloss that deepens over time. Finally, let your car cure undisturbed for 24 to 48 hours before exposure to water or heavy use.

Pro Tips for Enhanced Results

Temperature is one of the most overlooked yet critical factors when applying ceramic coatings. Ideal application temperatures usually hover between 15 and 24 degrees Celsius. Too cold, and the coating's chemical bonding slows, leading to incomplete curing and a dull finish. Too hot, and it can cure too quickly, causing streaks or uneven coverage. Setting up your workspace in a climate-controlled garage or shaded area is essential for reliable, high-quality results. Layering your ceramic coating transforms protection from adequate to exceptional. Instead of applying one thick layer, apply multiple thin coats. Each needs its own curing time, generally about 24 hours, allowing the polymer chains to set fully before adding the next layer. This buildup creates a stronger, denser molecular bond that amplifies hydrophobic performance and UV resistance.

Perform a meticulous final inspection after application. Industry professionals frequently use a high-powered LED flashlight to scan every inch of the vehicle's surface under sharp lighting conditions. This reveals any high spots where excess product has gathered or missed patches that could compromise protection. Catching these early lets you carefully buff them out while the coating is still fresh. Finally, patience and thoughtful timing are your best allies throughout this process. Rushing steps like wiping off excess coating prematurely or layering before full curing diminishes the coating's lifespan and can cause cloudiness or patchiness. Setting aside quality time over several days will reward you with a glass-like mirror finish and durability that lasts years longer.

Impact of Prep on Gloss and Durability

Meticulous preparation reflects profoundly on the ceramic coating's final gloss and longevity. When you carefully wash, clay, polish, and decontaminate your vehicle's surface, you're creating an ideal canvas for the coating to bond at a microscopic scale. This directly affects how long the coating will protect your paintwork. Properly prepped surfaces achieve significantly increased durability compared to those where prep was rushed or incomplete. The polishing process creates a perfectly smooth surface that allows the ceramic coating to settle evenly. Without this step, even the best ceramic formulas struggle to produce their signature high-gloss effect because underlying issues distort how light reflects.

Proper surface preparation also facilitates a stronger chemical bond between the ceramic coating and the paint substrate. This bond acts like invisible armor, resisting harmful UV rays, acid rain, road salts, and other corrosive elements that would otherwise degrade your vehicle's finish. Investing time and effort into prep routines translates directly into both immediate beauty and extended protection of your vehicle's paintwork. Ultimately, how well you prepare your vehicle will determine how spectacular and lasting the results become. Treat preparation as an essential part of the process because it is where performance truly begins.

Expert Ceramic Coating Services in Redmond, OR

Perfection Plus Auto Salon offers

professional ceramic coating services in Redmond, OR for drivers who want lasting exterior protection and a refined, high-gloss finish. Their skilled technicians focus on proper surface preparation and precise application, helping the coating bond effectively for improved durability and easier upkeep. Designed to reduce the effort required to maintain your vehicle’s appearance, these ceramic coating services are ideal for cars, trucks, and SUVs that deserve consistent care and long-term visual appeal.

Schedule your ceramic coating appointment with Perfection Plus Auto Salon today!